Mô tả

Information

Technical data

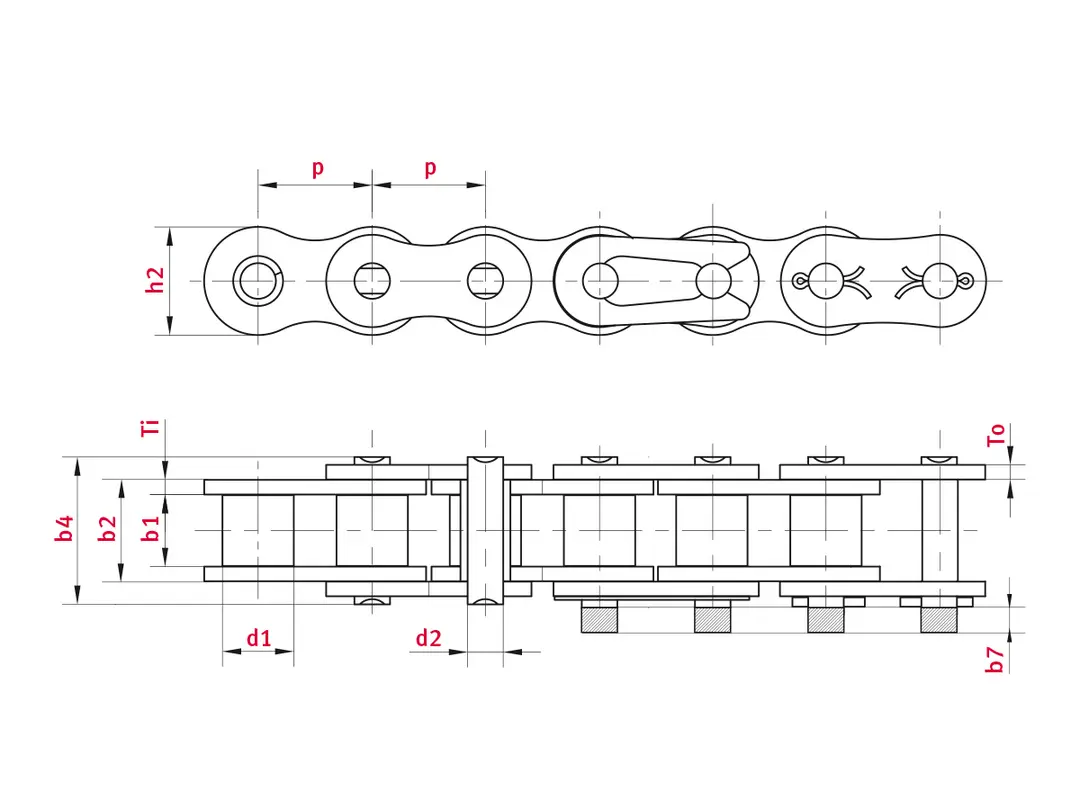

| Product name | Technical Data | Parameter |

| ROLLER CHAIN 60 | Pitch p (mm) | 19.05 |

| Width between inner plates b1 min. (mm) | 12.57 | |

| Roller diameter d1 max. (mm) | 11.91 | |

| Pin diameter d2 max. (mm) |

5.96 | |

| Pin length b4 max. (mm) | 26.9 | |

| Max. add. length of connecting link b7 max. (mm) | 4.6 | |

| Plate thickness Ti/To (mm) | 2.40/2.40 | |

| Height inner plate h2 max. (mm) (JWIS: g) | 18.1 | |

| Min. tensile strength ISO/DIN FU (kN) | 31.3 | |

| Avg. tensile strength FB (kN) |

39 | |

| Weight per meter (kg) | 1.5 | |

| Bearing surface f (cm²) | 1.05 |

Product Information

The new zinc-aluminium coated chains “ZAP coated chains” have the best corrosion protection of all coated chains. The typical lamellar structure of these coatings provide a so-called “barrier effect” and high cathodic corrosion protection without the risk of hydrogen embrittlement. The coating also has a positive effect on friction in the chain bearing. The new ZAP coating will replace the previous Geomet and Dacromet chains.

Product highlights

- The dimensions of all zinc-plated and nickel-plated ELITE-chains comply with the requirements of ISO 606 and the chains are interchangeable with standard chains

- Zinc-plated and nickel-plated chains are prestretched to 30 % of breaking load

- All chain plates are tapered and zinc or nickel plated

- Chains are fitted with seamless rollers; zinc or nickel plating available

- Pins offer a high level of corrosion protection and wear resistance

- The load capacity of zinc- or nickel-plated ELITE chains is similar to that of comparable standard chains

- Both chain types are generally supplied lightly oiled

Applications

- Packaging industry

- Solar and energy technology

- Wood processing industry

- Environmental technology, Recycling