Mô tả

Information

Technical data

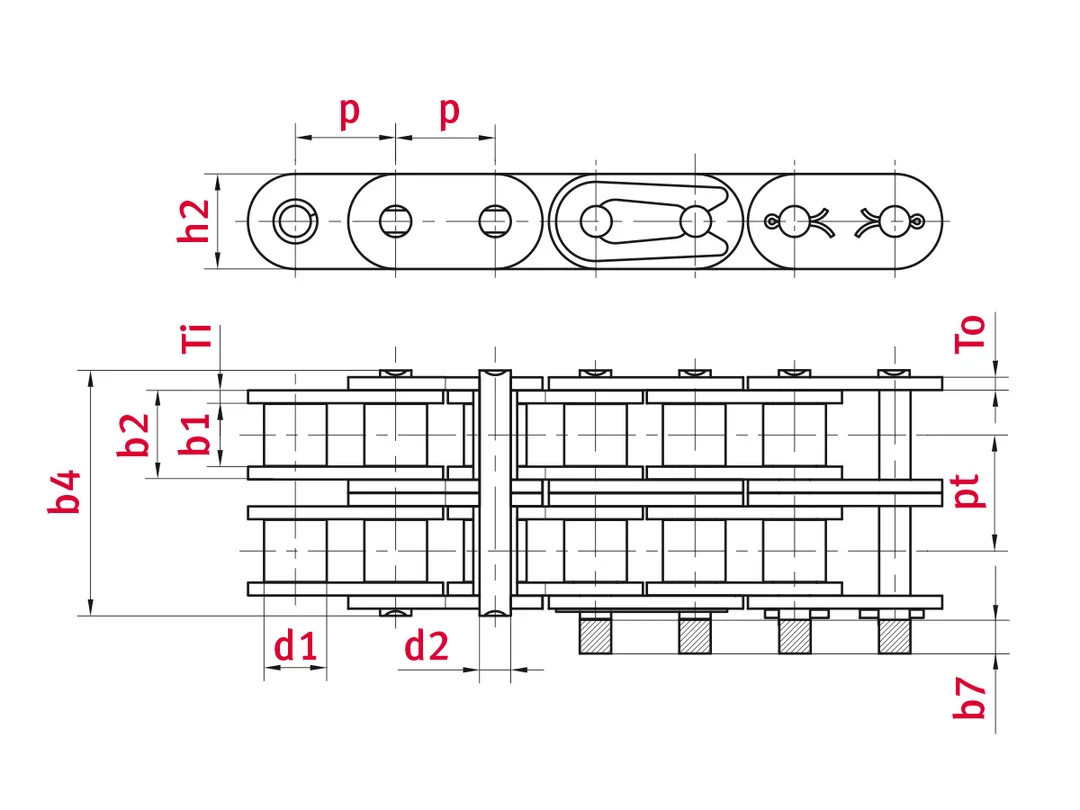

| Product name | Technical Data | Parameter |

| Pitch p (mm) | 19.05 | |

| Width between inner plates b1 min. (mm) | 11.68 | |

| Roller diameter d1 max. (mm) | 12.07 | |

| Pin diameter d2 max. (mm) | 5.72 | |

| Pin length b4 max. (mm) | 42.2 | |

| Max. add. length of connecting link b7 max. (mm) | 4.6 | |

| Total width inner link b2 max. (mm) | 15.62 | |

| Plate thickness Ti/To (mm) | 1.85/1.85 | |

| Height inner plate h2 max. (mm) (JWIS: g) | 16.13 | |

| Min. tensile strength ISO/DIN FU (kN) | 57.8 | |

| Weight per meter (kg) | 2.62 | |

| Bearing surface f (cm²) | 1.79 | |

| Traverse pitch pt (mm) (JWIS: e) | 19.46 |

Product Information

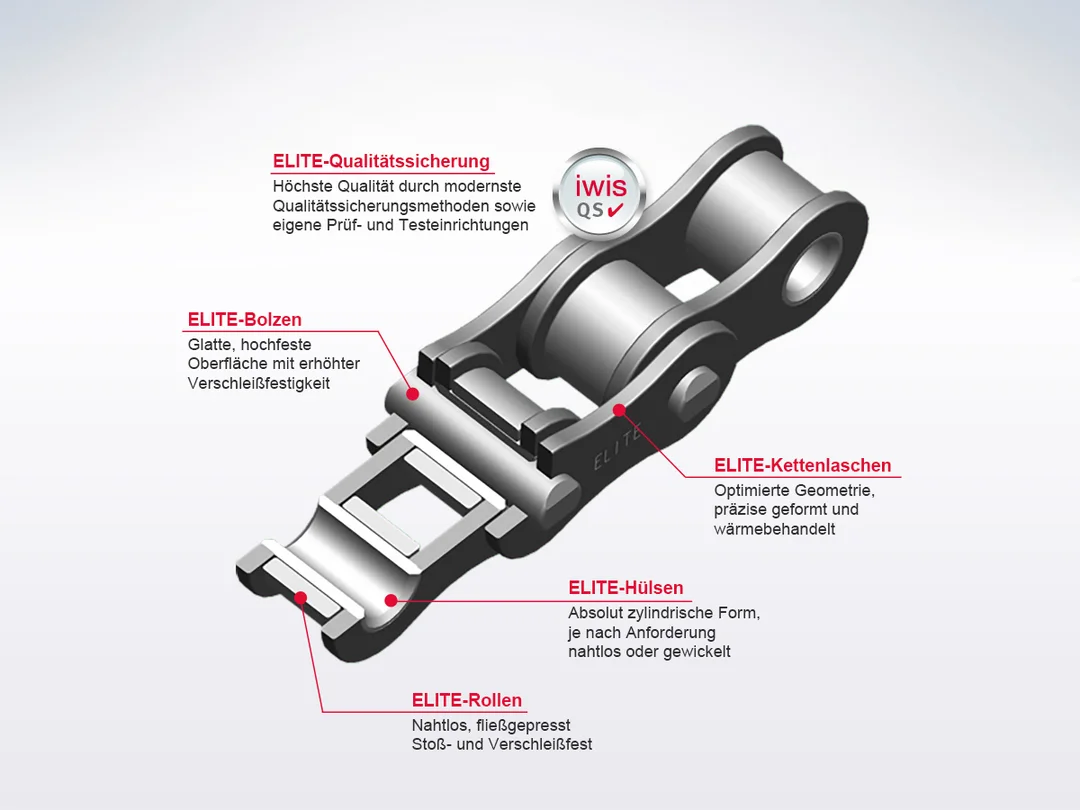

ELITE roller chains have a high wear resistance and significantly higher fatigue strength than the standard requires. The right choice for industrial applications: robust and reliable. All ELITE transmission roller chains are highly pre-tensioned and treated with our special additive chain oil eliDUR+, a high-tech initial lubricant. Non-drip eliDUR+ offers not only the added advantage of improved running characteristics, but also provides better corrosion protection.

ELITE highlights:

- Approx. 40% higher breaking strength is applied to pre-stretch our chains by 10% more than required by standard ISO 606

- Initial lubrication with eliDUR+ ensures extremely high wear resistance

- Low run-in elongation

- Tensile strength on average 20% higher than required by standard ISO 606

- ELITE pins have a smooth, extra- hard surface for increased wear resistance

- Operating temperature range with eliDUR+ standard lubrication: -5 °C to +70 °C

- All versions also available in coated form

- If required, we can deliver your chains ready-made to the desired length

- Special lubricants for low temperatures down to -30 °C or high temperature applications up to +250 °C available on request

- On request, iwis delivers chains pair-matched or set-matched and marked

Applications

- Warehouse technology, materials-handling industry

- Conveyor technology

- Assembly and industrial handling systems

- Wood processing industry